Da quell‘articolo è passato un bel po’ di tempo senza novità significative.

SpinLaunch ha pubblicato alcuni video dei lanci suborbitali di prova che ha

effettuato, come questo, che si

riferisce a un test del 27 settembre 2022, in cui ha lanciato dei carichi

sperimentali di NASA, Airbus U.S., Cornell University e Outpost. Non è stata

indicata la quota raggiunta, ma le notizie (Space.com) parlano di accelerazioni di circa 10.000 g e di una dimostrazione della

realizzabilità di carichi utili in grado di sopportare queste sollecitazioni

usando componenti standard. I carichi sono stati recuperati con successo.

Questo è stato il decimo lancio di prova effettuato e il primo con carichi di

terze parti.

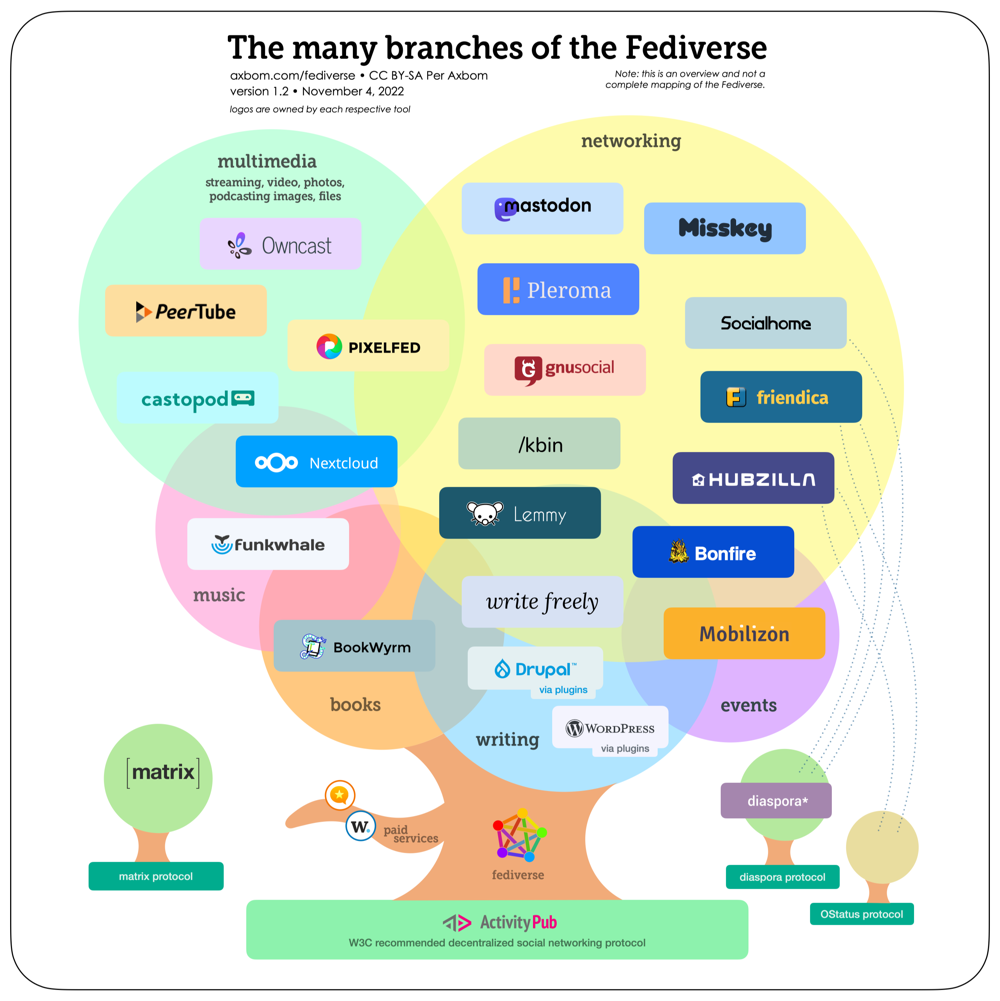

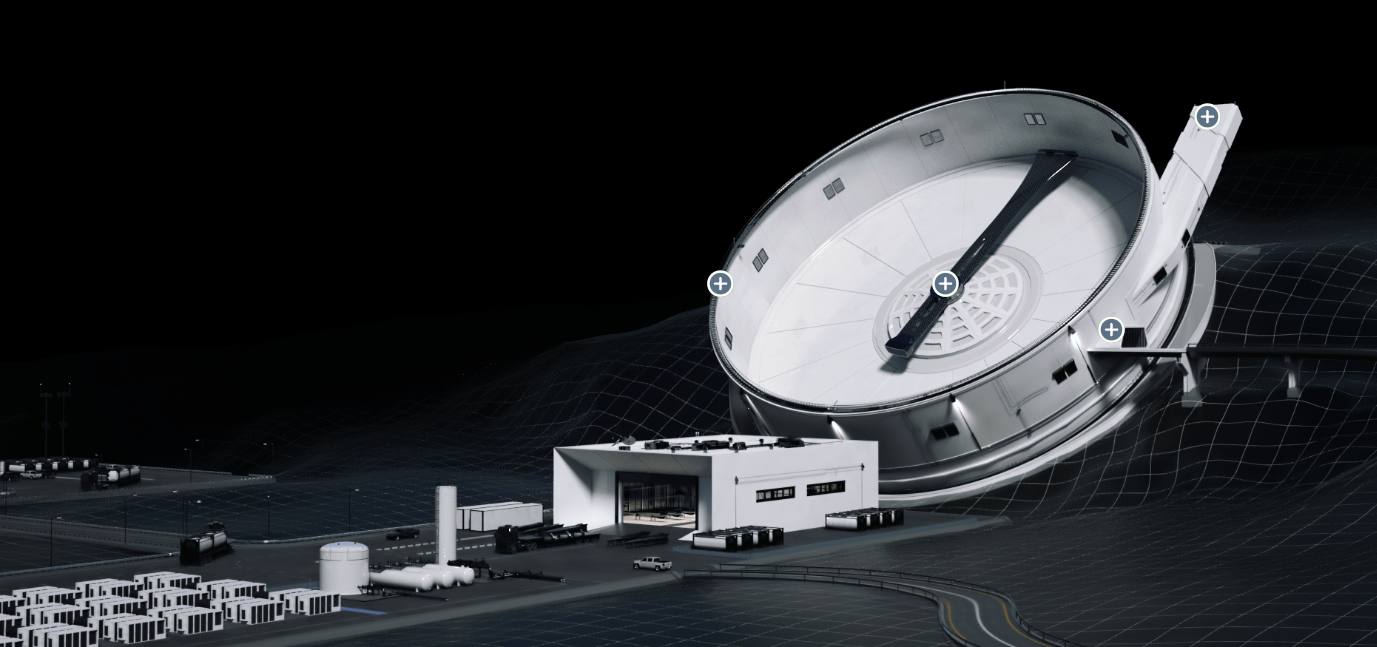

In questa illustrazione il coperchio della camera a vuoto è rimosso per

mostrare il braccio rotante interno.

Non è difficile notare che quello che Spinlaunch ha costruito e propone di

costruire è non solo un lanciatore di veicoli spaziali, ma anche in sostanza

un cannone elettrico, che spara proiettili ipersonici. Se li lanciasse

angolati, anziché verticalmente come sta facendo, avrebbero una gittata non

trascurabile, e sarebbero dei proiettili assai difficili da intercettare. La

soluzione di usare un braccio rotante, invece di un acceleratore lineare come

nei cannoni elettrici militari (railgun) attuali, riduce il picco di energia elettrica richiesto, dato che il

braccio può essere portato alla velocità di lancio gradualmente. Le

applicazioni e implicazioni militari, insomma, non sono trascurabili, anche se

le velocità di lancio raggiunte finora da SpinLaunch sono inferiori ai 12.000

km/h dei railgun lineari. Non a caso

Wired.com

nota che nel 2019 il Dipartimento della Difesa statunitense ha siglato un

contratto con SpinLaunch per lo sviluppo della sua centrifuga.

Inoltre un sistema del genere sarebbe molto interessante se installato sulla

Luna o su altri corpi celesti che non hanno un’atmosfera densa o non ne hanno

affatto: costituirebbe un metodo efficace per lanciare carichi senza dover

portare o fabbricare propellente, senza sollevare polvere superficiale al

decollo e senza contaminare la zona di lancio con il proprio scarico di gas

combusti, evitando la necessità di collocare il sito di lancio lontano dalle

strutture abitate (sarebbe sufficiente metterlo dietro una collinetta che

conterrebbe eventuali malfunzionamenti catastrofici). L’energia per

alimentarlo sarebbe elettrica, e quindi generabile in loco usando dei pannelli

solari e un sistema di accumulo.

Questo video è lungo ma contiene moltissime immagini e informazioni tecniche

molto utili:

Da qui in poi non ho avuto tempo di impaginare per bene, ma ho sistemato gran parte degli

errori:

Like holding a carbon fiber brick.

I don't think there's... I've never seen an

application where that much carbon fiber has

been laid up.

It's, it's rare to see carbon fiber this thick.

Yeah.

It really is rare. The final fully scaled

tether for SpinLaunch’s orbital system is

likely going to be the single strongest tensile

structure on earth. Let’s do the math on that.

SpinLaunch aims to [release?] its aeroshell, containing

the miniaturized rocket system, at about Mach

6, that’s roughly 2 kilometers per second. With a radius of 45 meters, the tether will

need to spin 450 times per minute to attain

that velocity. At that rate the g loading on the tether will

be 10,000 gs.

Meaning this aeroshell is going to exert a

force 10,000 times greater than its weight

due to gravity.

The aeroshell with the payload and rocket

is going to weigh approximately 10 metric

tonnes. So that means the tether, at the tip,

is going to need to be able support 100,000

metric tonnes, or 100 million kilograms. To put that into context, a fully loaded Falcon

9 weighs about 0.55 million kilograms, so

this tether is going to need to support the

equivalent weight of 182 Falcon 9s.

This is going to require a hefty piece of

carbon composite with cross-sectional area

of at least 0.23 meters squared.

That explains the brick of carbon fiber we

saw.

That brick could support about 4.1 million

kilograms. So the full scale tether will need to be 24.4

times this size at its tip, but that’s just

the tip.

This equation tells us why carbon fiber is

so vital to this endeavor.

Because each section of the tether has to

support the section above it, its strength

to weight ratio needs to be exceptional. If we calculate the tether area near the hub

for the same carbon composite, the tether only

needs to increase in area by 2.5 times, at

about 0.56 meters squared. We would of course need to add a safety factor

of at least 1.5 to this, increasing these

dimensions by 50%.

I have skimmed over this equation here, but

if you want to learn more about the engineering

of this system, and energy of getting to space

in general, I have created an entire course

on Brilliant to partner this video, and you

can sign up for it with the link in the description.

That design is perfectly feasible and is reflected

in SpinLaunch’s renders. We even have the manufacturing skills necessary

to build even larger composite structures, thanks to the wind industry.

So, this is all well and good, but spinning

a carbon fiber composite up to Mach 6 isn’t

possible in air. The aerodynamic heating would destroy it. So, to solve this issue,

SpinLaunch created a massive vacuum chamber

around its tether.

"You know, there's a bunch of things at the

beginning of SpinLaunch that were nonstarters

for a lot of people, like even just building

a large-diameter vacuum chamber.

You know, people were telling us, you know,

the one behind me here would cost tens of

millions of dollars to build. And we ended up doing it.

You know, we had this really, really kind

of scrap-heap mindset. And we ended up doing it for less than a couple

million dollars with ten people.

Right. Which is unheard of.

There's some large industrial

vacuum chambers out there.

But there's, you know, quite a few of the

really large chambers around the world are

for aerospace applications.

And so they're achieving extremely high levels

of not only vacuum, but cleanliness.

And so the cost is proportional to that.

And it's kind of exponential.

You know, they're achieving vacuums that are

on the order of ten to the negative 8 millibar torr. And, you know, typically we're operating at

about a million times worse than that."

SpinLaunch is breaking new ground with this

kind of vacuum chamber.

Typical large-volume vacuum chambers, like

the world’s largest one at the Space Power

Facility in Sandusky, Ohio, are designed to

simulate the vacuum of space.

Those require an extremely low pressure vacuum,

with tight tolerances and control of contamination.

They even need specialized tools like lamps

to simulate the radiation and heat emanating

from the Sun and cryogenic cooling to simulate

the heat of space. The people that built these facilities are

the industrial experts SpinLaunch had to draw

from, and most thought they would never be

able to build a vacuum chamber this large on

their budget.

But SpinLaunch had some things on their side.

They didn’t need that extreme of a vacuum,

as their goal is not to simulate the vacuum

of space. Their goal is to minimize drag and the power

required to overcome it, minimize the aerodynamic

heating that would destroy the tether, and

eliminate all those pesky aerodynamics effects

like flutter. That means SpinLaunch could use cheaper materials

like mild steel, where ultra high-vacuum chambers

need more expensive specialized processed

materials to avoid outgassing,

where gases within the metal in the form

of oxides, or simply dissolved within the

metal, are released into the vacuum.

It also makes the process of drawing a vacuum

much easier. Drawing a vacuum isn’t as simple as just

turning on a pump and leaving it on long enough. The more air you draw out, the harder it becomes, as you are not only working against a continually

growing pressure gradient, but statistical

probability.

The first stage of drawing a vacuum is to

remove the bulk gas. At this stage the gas

is a viscous fluid, and the molecules within

the chamber interact with each other often. Here we can use traditional fluid flow pumps,

like a positive-displacement pump,

that mechanically moves molecules out of the

chamber, and higher-pressure air at the back

of the chamber forces more air to fill the space

created, allowing more air to be pumped out.

But as gas is removed from the chamber, the

distance between the molecules increases. This is called the mean free path: the distance a molecule can travel without

colliding with another molecule.

Now, pressure is really just molecules colliding,

and as collisions become more infrequent,

the pressure gradients that are needed to

achieve equilibrium begin to vanish,

meaning it takes longer and longer for equilibrium

to be established, and the rate the pump can

remove molecules lowers, as there are simply

fewer and fewer molecules near the pump to

remove. At some point viscous flow stops entirely

and we enter a flow regime called molecular

flow, where the distance between collisions is actually

larger than the internal dimensions of the

vacuum chamber.

Meaning, the molecules are statistically more

likely to just bounce inside the chamber with

nothing forcing them towards the exit. At this stage it is impossible to actively

pump the molecules out.

The molecular pumps needed for this flow regime

instead act like some kind of Venus flytrap,

waiting for a molecule to enter it, and then

its job is to prevent the molecule from returning

to the original chamber. Turbomolecular pumps are basically multiple

levels of turbines that knock molecules in

one direction and prevent them from traveling

backwards. These pumps require insane rotation speeds,

anywhere from 36,000 rpm to 72,000 rpm, and

need incredibly tight tolerances too; they

are trying to pump individual molecules after

all. So, it goes without saying, these kinds of

pumps are expensive.

All the while, outgassing and other leaks

are actively working against the game of pure

chance. Creating a high vacuum requires extreme precision

in manufacturing and design. SpinLaunch didn’t need any of this.

Mark Sipperley, the director of Engineering

at SpinLaunch, walked me through the vacuum

pump station at the New Mexico site.

"Here in the vacuum plant the, the most familiar

thing would be the tube that came out of the

chamber and then runs underground in this

manifold.

So this is the very end of it.

So off of this vacuum manifold, we then have

a series of three different types of pumps. Up on top we first have roughing pumps, which

pull the atmosphere of like one atmosphere

down to about 30 millibar. Those are dry screw pump that are essentially

like overlapping lobes.

It's it's one form like a turbocharger.

Then the next stage is we have this Roots

pump, which is, which is like a yeah, another

shape of a turbocharger. It's like this the rotating twin screw pumps

okay.

So that kicks on at about 30 millibars.

So it's mostly only in it's 30 millibars below.

But you'll notice that each pump, it exhausts

into the pump like a pump, that's a slightly

higher pressure.

So this Roots pump only works in 30 millibars

below, but it can't exhaust all the way up

to one atmosphere.

So that's backed by another piston pump

So this this would also be like a great roughing

pump.

So when we turn on the first system, we have

nine Edwards GSX pumps up there, and then

this piston pump.

Sorry, both of these piston pops when we get

down to 30 millibars, which we turn on a series

of Roots pumps, which is this guy right here.

And we have another smaller one on this one.

These pistons are also running as well.

And then once we get down below one millibar

they're going to turn on these vapor diffusion

pumps, which only are really effective down

at the very low pressure.

Those work like oil jets.

So you vaporize oil, you shoot it down a series

of channels and it grabs onto the air molecules,

runs them down a series of tubes and then

you have these cooling loops that will then

condense out the oil and then the water, or

sorry, the air progressively makes its way

through like a long path, and it eventually

goes to a Roots pump, which can grab on

to it, and then it goes to a piston pump,

then all the way out.

So we talked before, you know, vacuum may not

be the best description. Most people think

of vacuum like a hard vacuum like in millibar, in

torr is what most people are used to like.

E to the minus -7 torr, like seven zeros are

six zeros.

And the number that's like true vacuum. That's hard vacuum, that's where you test

like, you know, like electric propulsion systems

and like high-end space features. That is nowhere near the atmosphere that we

need.

And that's that vacuum is also really expensive

to get to. We have to follow a lot of stringent rules

like you can't use steels, you have to use

aluminums and use coatings. You know, even like putting your fingerprint

in an atmosphere in a vacuum that low, will

take weeks to boil off. We only require the equivalent to the minus

3 torr or as a .01 millibar or .1 millibar. Today we're going to be running at like one

millibar.

We only pull the vacuum that we need, because a

vacuum is expensive. So it’s is closer to describing it like

a high atmospheric chamber than a vacuum chamber

specifically.

And then it will be the same.

And again, that's all driven by the aerothermal. That's all that's the only vacuum that we

needed to accomplish. So on the orbital system, we'll probably pull

a very similar vacuum, we don’t have to

go much deeper, there’s no benefit to going

lower."

This is another one of those technical issues

that the internet made a big deal out of,

without fully understanding what SpinLaunch

actually needed out of the vacuum chamber.

One of the other primary concerns expressed

on the internet was the tricky and unique

problem of a vehicle traveling at hypersonic

speeds from a vacuum into a thick sea level

atmosphere.

To begin with, we need to prevent air from

rushing into the vacuum chamber once the vehicle

is released. SpinLaunch is aiming to be a high-frequency

launch system, capable of launching multiple

satellites per day, holding the vacuum between

launches to decrease energy and time costs. However, the primary concern is the disastrous

effects that air would have as it meets the

tether spinning at hypersonic speeds. This would be an incredibly expensive single

shot system if this was allowed to happen.

To solve this problem, SpinLaunch needed a

way of sealing the chamber extremely quickly

after launch, so inside this long tube attached

to the vacuum chamber is a double-door airlock,

with doors on either end of the tube. This tube is also under vacuum during spin-up.

As the vehicle is released, using a release

mechanism that SpinLaunch kept hidden from

our cameras throughout the shoot, it passes

into the exit tunnel, where the first door

rapidly closes behind it. As this first door is closing, the second door

will begin to open. The atmosphere will begin rushing into the

tube and give the aeroshell its first taste

of the hypersonic flight regime it will be

flying in. The first and second door need to close quickly

enough to prevent air from entering the vacuum

chamber.

This is not an easy problem. Millisecond delays that may seem trivial in

most cases start to mount up when the vehicle

travels this quickly. The time it takes for an electrical signal

to propagate, the time it takes to overcome

the inertia of the door, the time it takes

for a proper seal to form. All these problems become matters of survival

at these speeds.

Once again, SpinLaunch are keeping their cards

close to the chest on this one, but they did

give me a demonstration of the door closing

in their factory and engineering hub in Long

Beach, California.

"Well, it’s it's moving really fast.

And so when the... when the you know, without

specifying, is he going to do a countdown?

You're ready for a countdown just let me know.

Yeah.

So basically what's going to happen is, you

know, this is going to be filled with, you

know, for lack of a better word, like a black

door which basically you'll see that like

you can pass through this with a vehicle and

then in an instant it's going to be close.

Okay.

So and again, it's like fast in the blink

of an eye.

So you'll see a little bit of settling as

a, as a after it closes.

But it's, you know, basically 95% close within,

you know, 30 milliseconds."

Oh wow, okay.

Closing the airlock.

[Static]

Speaker

Closing airlock in five, four, three, two,

one.

[LOUD BANG]

It's pretty fast.

Yeah that is not what I was expecting.

[Laughing]

Yeah, it's fast.

So that actually closes.

Like, it's actually hinged.

There's a pivot.

Yeah, there's a pivot involved.

Yeah I wasn’t sure if it was going to be

a sliding thing.

But the hinged one makes sense as well.

Yeah, that wasn't that what I was expecting.

Yeah.

So it’s 100% reusable, so you can set that

back up again and do it again and again and

again.

So that's a key aspect of it is that you don't

have any major consumables in the process.

So, so that's fast. Visceral.

All right.

[Laughter]

It’s a door closing.

I don't know what to ask.

It's really important not to let everybody

back in.

So that's you know, that's why we have it.

Oh, everybody jumps.

You can’t not.

Yeah, yeah.

"So, you know, the airlock is a really critical

subsystem of the overall, you know, of the

overall architecture as you travel from vacuum

into the atmosphere because the tether is

still rotating at high velocities, you want

to maintain the vacuum inside of the vacuum

chamber. And so the airlock is your first line of defense

for that. And so we have multiple redundant airlocks just like what you see here that the vehicle

passes through and it subsequently closes

behind the vehicle, you know, preventing the

air from in-rushing and reentering into the

vacuum chamber. And so that the exit tunnel is really the

only portion of the chamber that experiences

a rise in pressure."

I imagine that allows you to reset and like

increase frequency of launches as well.

If you're not having to re…like..

"Yeah, totally.

So you can, you can do, you know, you can

essentially provide a, you know, an airlocked

space for the end of the tether as well.

And so you can basically just re-pressurize

that space as you load in new vehicles.

It's possible you could do vehicle integration

in vacuum.

But currently we're... we're anticipating actually

repressurizing a small portion of, you know, interfacing

around the tether. Repressurising a small portion and integrating

the vehicle without it being in vacuum or."

What do you actually see the like how many

launches a day do you think you can manage?

I think that's like one of the advantages

of this that you can yeah.

"I think on the very high end, it's upwards

of ten. I think on the low end, it's, it's, it's about

five is a pretty good nominal target for us. We see viability there."

In SpinLaunch’s public videos, the secondary

air lock has simply been sheets of mylar. This is one of the few problems that becomes

easier as the launcher scales. As the exit tunnel grows in length, it will

take air longer to reach the door at the base

of the exit tunnel. SpinLaunch have only just begun these one-third scale

tests, with their fastest launch

to date at 1.6 Mach, slowing ramping up the

speed of launch as they test their systems. This prototype launcher features some other

simplifications compared to their final planned

configuration.

One of the most obvious problems to tackle

is the issue of vibration. When a spinning object's weight is not evenly

distributed it will vibrate. This is how rumble feedback works in gaming

controllers.

A simple electric motor with an uneven weight

attached. However, with a structure as large as SpinLaunch’s

tether, spinning several times per second,

any imbalance could shake the entire structure

to the ground. This is a major problem, because by design

the tether releases a 10-tonne weight right

as it hits its maximum velocity. SpinLaunch needs a way to balance the tether

after launch.

There is a very simple solution to this problem

though.

Release a balanced weight from the other side

of the arm at the same time. Right now they are simply releasing a counterweight

that slams into an armored section of the

vacuum chamber. We saw one of these counterweights being manufactured

out of fiberglass in the Long Beach factory; however, over the long term having to clean

up the mess this creates after each and every

launch is far from ideal.

The ideal solution would be to release a counterweight

in the form of another launch vehicle after

a single half rotation of the tether. The oil-filled journal bearing the massive

axle sits upon should be able absorb the force

of this imbalance over a period of time this

short.

The next issue we need to concern ourselves

with is the aeroshell punching into the atmosphere

at Mach 6. This, again, is a fairly unique problem. Typically weight is a restraining factor in

aerospace, but for SpinLaunch the energy required

to spin the aeroshell up to speed is actually

rather trivial.

"And I like to use the analogy of like a Tesla,

right? So the Tesla Model S Plaid is about 0.7 megawatt. So on the low end, it's about 100 Teslas but

it really comes down..."

Is that the full scale?

Yeah, for the full scale.

Yeah, yeah, yeah.

"For the orbital system you're talking about like on the low

end.

On a very low end. You know, it's probably about 65 to 70 megawatts.

And again, that really depends on where you

end up with the final orbital tether, you

know, whether or not you, you know, what,

what safety factor you

operate with.

What, what, you know, what tether strength

you end up with your effective tether, cross

sectional strength that all feeds back into

itself.

And then you have to kind of scale it accordingly.

I would say like really conservatively, like, you know, if you wanted to spin

up really fast, then you're talking about

higher power demand.

So whether you want to speed up in an hour

or 2 hours, you know, proportionately makes

a difference of of how much power that you

need.

So but, you know, on the high end, you're

talking about maybe 150 megawatts of

power, which is like...

I don't know, maybe in layman's terms, it

sounds significant, but, you know, you can

you know, there's, you know, there's motor

catalogs where you purchase you know, the

motor that that has that capacity.

Right. And so this is, you know, it's industrial

scale hardware and certainly, you know, mostly

off the shelf."

Do you need to worry about grid integration

at all when you're when you're suddenly drawing

that much power?

"For better or for worse, no, because you're typically, you know, particularly

for for early, you know, orbital accelerators

that we're building, we're expecting them

to be in really remote locations, kind of

remote coastal locations. Green field sites that don't have substantial

existing onsite, you know, resources or power. So you're you're basically, you know, bringing

your own power. You you know, and so you have to, you know,

decide on, you know, what is your energy source

or are you doing energy recapture, you know,

etc.."

SpinLaunch claims their total energy demand

per spin-up is about 100 MWhrs.

The cost per kilowatt hour for industrial

facilities is about 6 cent.

So that’s a cost of 6000 dollars in electricity

cost.

That’s insanely cheap. To put that into perspective, 100 megawatt

hours is equivalent to about 9600 litres of

kerosene, about 8 tonnes of fuel.

For reference, the Electron Rocket from New

Zealand's small-satellite launching company

Rocket Lab, capable of launching a similar

sized satellite, weighs a total of 12.5 tonnes, the vast majority of that weight being its

own fuel and oxidiser.

SpinLaunch claims their rockets will need

to carry about 30% of the fuel and oxidiser

compared to these competitors. They are essentially replacing the first stage

of a traditional rocket with an easily reusable

kinetic launch system.

SpinLaunch will also be able to recapture

a good deal of the electricity stored as kinetic

energy in the tether, using regenerative braking, even further reducing their electricity bill.

Because of all this, the limiting factor for

SpinLaunch in terms of weight is actually

the weight the tether can support, and as

a result, it actually makes sense to maximize

the density of the aeroshell, because it affects

a variable that will drastically improve its

ability to punch through the atmosphere: its ballistic coefficient.

Ballistic coefficient is essentially an object's

ability to resist air resistance. Think about how hard it is to throw a feather.

No matter how hard you throw it, it’s not

going to go very far.

It’s got a large surface area for air resistance

to act upon relative to its weight.

That’s a low ballistic coefficient.

Ballistic coefficient is found by dividing

the mass of the projectile by the drag coefficient

multiplied by the cross-sectional area. So SpinLaunch effectively wants to maximize

the mass relative to the cross sectional area.

This is obviously not typical for aerospace

vehicles.

"If you, if you look at reentry capsules whether

it's for something like the Stardust return

capsule where it's really, really high velocity

or you look at it reentry from orbit for a

manned capsule or something like the Space

Shuttle, they're typically using thermal protection

systems that are extremely low density, like

on the order of less than 300 kilograms per

cubic meter.

It's just basically foam.

And so... so typically that means you're making

like significant compromises, like.

The material often is,

You know, brittle or prone to fracture you

know, or really expensive or gets worn away.

And then you have to replace the tiles, kind

of in the infamous case of the Space Shuttle. So what we're dealing with is, you know, you're

on the tip of the vehicle you have, you know, materials like copper,

which, you know, not only are they, you know,

a significantly higher density, right?

You're talking about, you know, thousands

of kilograms per cubic meter, but they also

have really great thermal conductivity.

So basically, as you transition through the

atmosphere, you have a high heat load, but

then you're dumping that basically into heavy, dense materials

that have good thermal conductivity."

This is one of those unintuitive consequences

of this style of launch. When I first saw the full-scale aeroshell

on the SpinLaunch factory floor, I first asked

if I could ride it like a cowboy, but then

immediately noticed the bi-metallic nose cone. I knew from looking at it that it was made

from copper and aluminum, and that struck

me as extremely odd. Those metals would melt at the temperatures

I associate with hypersonic speeds. But, because SpinLaunch launches at Mach 6,

it actually transitions through the lower

atmosphere rather quickly, and as a result,

the heat generated can simply be absorbed

by these large heat sinks. Aluminum and copper's high thermal conductivity

means the heat is distributed through the

body of the aeroshell before it has a chance

to damage the vehicle.

The hefty carbon fiber shell is also incredibly

strong. SpinLaunch has already pulled their smaller

scale aeroshells out of the ground, buried

several feet deep from the force of impact,

and reused them with minimal refurbishment. With a parachute, these aeroshells will be

fully reusable with minimal maintenance, especially

as they serve no function other than to protect

the inner rocket’s stages. This isn’t an intricate mechanical machine.

Launching from the ground at these speeds

comes with advantages too. If we plot drag coefficient vs Mach number

for a bullet-like projectile, something rather

unintuitive occurs. The drag coefficient rises as you would expect

up until we hit Mach 1; at this point it starts

to fall as Mach number increases.

This is the equation for drag.

It’s proportional to drag coefficient, air

density and velocity squared. With drag coefficient being lower at hypersonic

speeds, it actually makes some sense to punch

through the thick lower atmosphere, where

the high-density air causes drag to rise,

as fast as possible.

Deceleration is a function of time after all,

meters per second square, meters per second

lost per second. Let’s calculate the dynamic pressure this

drag would create at launch, and the deceleration

it would cause. The dynamic pressure is found by multiplying

air density by the velocity squared and dividing

by 2.

At sea level, at Mach 6, the dynamic pressure

will be 2.6 megapascals.

The final aeroshell is 1 meter in diameter

and has a drag coefficient of about 0.1, which means the force applied to the aeroshell

at launch will be 205 kNs.

This sounds like a lot, but here's where the

ballistic coefficient comes in.

This drag force is being applied to a 10 tonne

body moving at mach 6.

That’s a lot of inertia.

Force equals mass by acceleration. Acceleration equals force divided by mass. That means high mass equals less deceleration. In this case, deceleration due to drag will

be about 19.8 m/s per second at launch, but

it will rapidly decrease as we move through

to thinner and thinner layers of the atmosphere

and lose velocity. In fact, with SpinLaunch’s planned trajectory,

we can plot the atmospheric density the aeroshell

will encounter over time: halfing in just 5 seconds, and dropping to

less that 10% of the original air density

in 15 seconds.

While gravity will remain more or less constant

at 9.8 m/s per second.

That means gravity losses form the majority

of energy losses in our transition to orbit. In total, SpinLaunch will lose about 150 m/s

of velocity to drag and 1000 m/s to gravity.

Satellites like Starlink orbit at 500 kilometers

with a velocity of about 7700 m/s, so even

if SpinLaunch maintained its 250 m/s velocity

from launch up until the aeroshell broke apart,

the two-stage rocket hidden within would still

have its work cut out for it.

However, now free of the mass of the aeroshell,

the substantially miniaturized rocket needs

only a fraction of the mass of fuel and oxidiser

to rapidly accelerate the 200-kilogram satellite,

the largest satellite this system can launch,

through the thin atmosphere at this altitude.

We can actually graph the relative velocity

of the spacecraft over time. Starting at Mach 6 at launch, and ending

up at about 1500 m/s when the aeroshell splits apart. The rocket motors then kick in to rapidly

accelerate the satellite to its 7700 m/s orbital

velocity.

The physics here absolutely checks out here,

but whether the economics and cost of development

will be viable is the big question to be answered. SpinLaunch has built a 1/3 scale prototype

at a relatively low cost, but the hardest

part of this technology is scale. They have reached 1.6 Mach thus far, have

tested their satellite components at 10,000 g

in their test facility in Long Beach, and

are continually upping their test parameters,

pushing further and further.

This is a comparison of SpaceX and SpinLaunch’s

proposed launch trajectory, but it doesn’t

tell the full story of the real driving issue

here, economics. A SpaceX launch to low Earth orbit costs about

67 million dollars. The heaviest Falcon 9 payload to date has

been 16,250 kg on a densely packed Starlink

mission. That equates to a launch price of about

4100 dollars per kilogram.

However, small satellite launch companies,

like RocketLab, who offer greater control

over orbit and launch schedules, charge about

15,000 to 25,000 dollars per kilogram. Dollars per kilogram is not a perfect metric,

but gives us some idea of the competition

SpinLaunch is facing.

SpinLaunch’s main competitive advantage

is in the decrease of expendable materials

like fuel while substantially miniaturizing

rocket components. They also have huge potential to launch far

more frequently than their competitors, helping

the economics of scale to kick in.

SpinLaunch claims to be targeting an ambitious

per-launch price in the range of half a million

dollars, placing them at 2500 dollars per

kilogram.

In my time in SpinLaunch, talking to their

engineers, it’s clear they are excited and

believe in this company. The basic napkin physics for SpinLaunch absolutely

check out, and they are well on their way

to solving the engineering challenges, but

scaling up this monstrous engineering effort

is going to require enormous amounts of investment,

and SpinLaunch could not disclose the answer

to many of my questions, as they seek patents

for their solutions.

I got little info on one of the most difficult

parts of the launch system, the release mechanism

for the aeroshell; even the 3D models SpinLaunch

provided for this video had the release mechanism

removed, so we had to model our own along

with the internal rocket structure. The design of the satellites is another problem,

due to the massive gs the satellites have

to survive, but g-hardening isn’t as large

an engineering challenge as the internet seems

to think.

"The most difficult part.

So besides the structure is, is also the reaction

wheel.

So the reaction wheel is, generates momentum

and basically steals the bus. And so it typically is a big mass that's cantilevered

up at a certain angle. So which is the one thing that we don't like,

you don't want having a big mass sticking

up on a can really."

This is what I assumed was going to be like

a difficult thing to because it inherently

has to be fairly high mass to control the

satellite.

Right.

"And so we've done a lot of work to instead

of re-engineering the wheel itself and figure

out different ways to do that, we basically

just took and created it took a clever way

of deploying the wheel. So we support the wheel in the flat orientation

and we spin. So when it's spinning, it's, it's well supported. The bearings are unloaded and so it can spin

and do its thing. And then we deploy the wheel for when it actually

used to operate.

So it's a it's a simple solution for what

could have been a really difficult problem."

And does the the axis of the actual wheel

cause any issues when it's like being loaded?

I imagine that's a fairly high weight to have

on the axle yeah.

"So we, what we do is we unload the bearings

and as part of the deployment mechanism we

actually move we reload the wheel into the

bearings."

Oh, okay.

So it's just taken off completely Okay.

"So again, trying to make simple solutions

for very difficult problems."

And like those are very simple answers, right?

Like I figured that the like the inertial

wheels would be difficult, not like you just

think about it as like, yeah, that's actually

a fairly easy thing to just not deal with.

You don't have to have it in the exact configuration

when you like launch, right? Same with the solar panels.You can have them,

like you said, loaded.

"Yeah.

So it's the problems aren't necessarily hard

to deal with.

It's just you have to think differently. We just have to change the way we think about

design.

So it's a little bit it's not a lot. The nice part is to that over the last 60

years, what people have been trying to do

with satellites actually has helped us because

they want to reduce mass. They want to make things stronger. So every bit that they're forcing them to

deal with shock and vibe already helps us. And it already inherently starts to make them

more hardened. Most components, we don't have to do anything

to them.

Maybe a little epoxy here but like we one

of the most surprising events that we have

here among the entire team is we took a board

that had a password stuck up, you know, maybe

a quarter of an inch.

And we all looked I was like, okay, that thing's

it's going to fly off the wall.

And we spun it and we brought it back and

it just went over and that was it.

And we are like, all right.

Our intuition is completely changing.

And yeah, and it's because it's, it's so little

mass and it's being held on by two pieces

of steel.

You know, the amount of force that that was

really imparting on those two piece of steel

was relatively small. So it just bent over and we all kind

of like, Oh, yeah, after you think about it,

it does make sense.

Okay. Yeah, that's right. So our intuition is starting to grow about,

yeah, this little connector of the sticking

up really isn't that big of a deal.

And so that has been in a positive way.

Very surprising."

Gs can only create force where there is mass,

and it turns out the satellite industry has

been finding ways to reduce mass for decades.

A simple aluminum can is capable of withstanding

10,000 gs with a basic redesign of its structure.

Minimizing weight located on unsupported surfaces

lowers the mass available to be multiplied

by the gs, and some simple corrugation can

help the aluminium absorb some of the loading

without buckling.

We spun up an off the shelf star tracking

camera using Spin Launch's in-house centrifugal

accelerator, which can already achieve 10,000

gs, and the camera worked perfectly fine just

moments later.

This is a really interesting engineering challenge,

that I think the internet is giving a hard

time for some bizarre reason, posing questions about basic physics calculations

without actually doing the math, and then

saying it’s impossible. Even missing the fact that kinetic energy

launch systems have already reached beyond

the Karman line 6 decades ago. [...]